Ball Gathering Mechanism: Learning the Hard Way that Less IS More

The Pulley and Ramp System That Just Wasn’t Meant To Be: Learning the Hard Way

We learned an important lesson about pulleys from this experience: they are not as easy to use and build as they look. Ambitious in our pursuit to have TTM collect actual tennis balls, our first design featured a pulley system and ramp. The idea was to have the pulleys lift the ramp thus dumping the balls into a box situated at the rear of TTM.

We struggled to make the pulley and ramp work. However, lego pieces proved to be too delicate a sort of building block to effectively lift tennis balls. The ramp and pulley worked flawlessly a grand total of ONE time; the rest of the time it wobbled up and down, the two pulleys pulling out of sync and the motors of the pulleys constantly coming unlose.

Exasperated, we stripped off the last two days of work and kissed the ramp and pulley system good-bye. We were back to square one.

The Thrasher that Saved TTM

The Friday before the Monday exhibition our situation seemed as dismal as Chrysler’s had been a couple decades ago. TTM just wasn’t gathering balls. After struggling to make a stubborn pulley and ramp work for two days, we decided to scrap both and start afresh. As Professor Anderson pointed out, throwing away an idea and its physical manifestation is HARD. That is when we came up with our “minivan idea:” a thrasher for ping-pong balls instead of tennis balls.

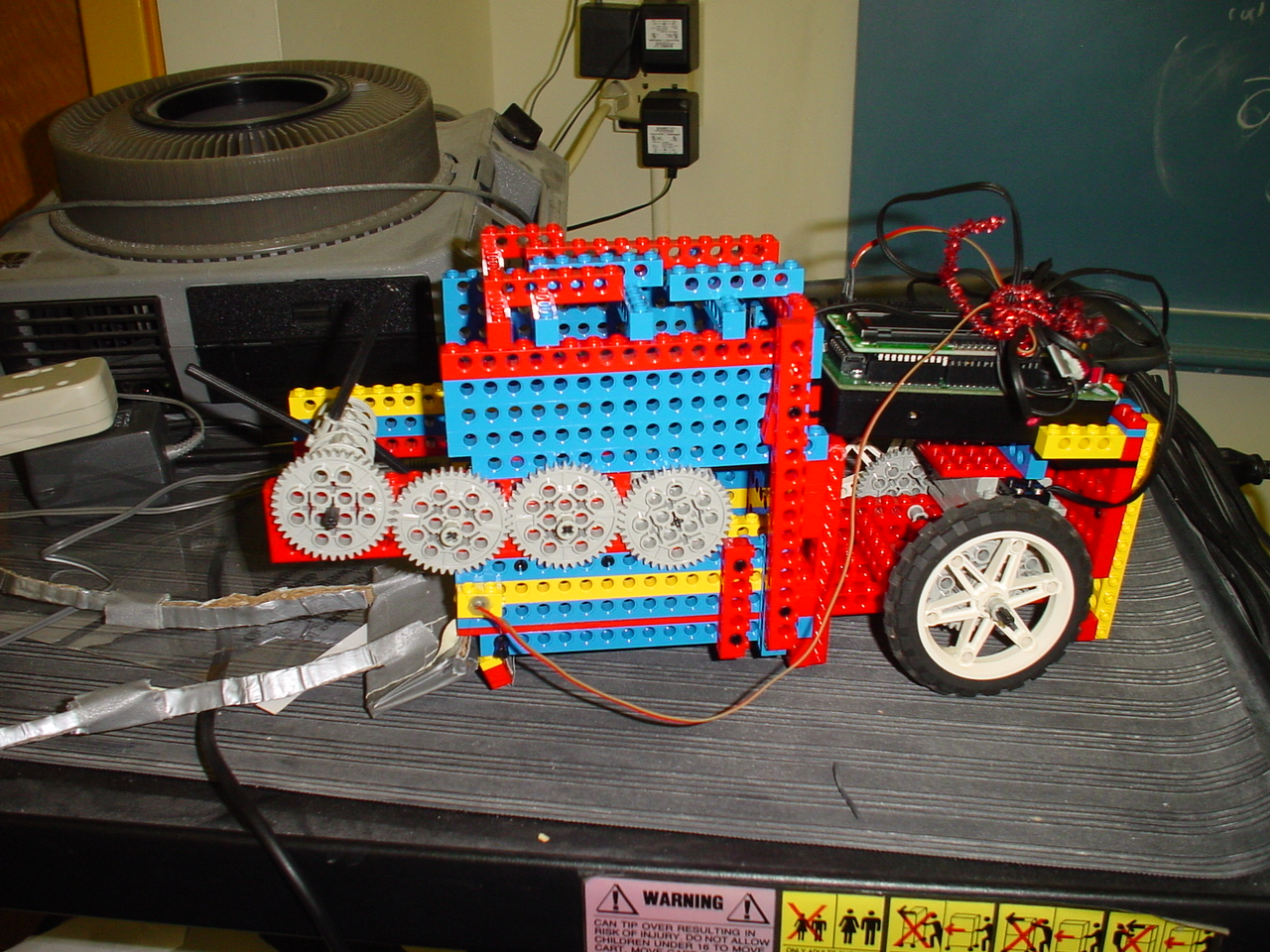

We got the idea for the thrasher from an MIT competition, which featured a robot that thrashed at ping pong balls to gather them. Going on this idea, Erica created the thrasher mechanism you see below. Made out of rods, bracings, and small wheels, the thrasher spins around rapidly pulling in ping pong balls.

hhhhhhhhhhhhhh

The thrasher runs on a separate motor from the wheels' motors. This motor, located within the ball collection chamber of TTM, is also one of the newer motors with internal gears. It is connected to the thrasher via a gear train that runs along the side of TTM, as shown below.

For the most part, the thrasher design was fairly hassle-free. We had to change the rod lenghts and readjust its placement a few times. The greatest problem with the thrasher was that the balls would often be repelled by it rather than being swept up by it; the balls had to be in exactly the right spot under the thrasher for it to grab them. This problem was eaasily fixed by attaching a ramp and 'antanae' designed by Roshni that guided the balls to the proper place beneath the thrasher. The antanae were made of flexible material (duct-tape covered cardboard strips) so that they would not break when they hit walls.

TTM could now gather ping pong balls.

For kicks, we decided to add a ball detector that counted the number of balls TTM gathered, and printed the number on the LCD screen of the handyboard. A red LED was placed across from the light sensor (see picture above), which was set at a threshold of greater than 100. When the light beam from the LED was broken, the threshold would increase beyond 100 and the handy board would beep and counted the number of times a ball went through the thrasher.